Transformer Core and Clamp Guide: Practical Insights for Manufacturers and Distributors

Why Transformer Core Design Matters

If you're in the transformer manufacturing business, you know one thing for sure - the transformer core is where everything starts. A well-designed core means better performance, higher efficiency, and lower energy loss. But it's not just about the silicon steel sheet you choose - the clamps, stacking method, insulation, and even bolt positions all play a huge role.

So today, let's break down the practical side of transformer cores and clamps, based on real engineering blueprints, and share tips that can help you in your factory.

What Is a Transformer Core, and Why Is It Crucial?

The transformer core is the heart of the transformer. It's made of cold-rolled grain-oriented (CRGO) or non-oriented (CRNGO) silicon steel, stacked to reduce eddy current losses. It guides magnetic flux and helps convert voltage levels smoothly.

Real-World Example

Let's say you're working with a 315kVA 11/0.4kV distribution transformer. The design on file shows stacked lamination in a 3-phase wound core arrangement, with cross arms holding the limb and yoke securely. You'll see things like:

Core window dimensions (the open space for winding)

Limb width and height

Stack thickness (mm)

Center-to-center limb distance

If these parameters are off, you might get humming noise, energy loss, or worse - overheating.

Types of Transformer Cores (with Use Cases)

|

Core Type |

Description |

Common Use |

|

EI Laminated Core |

Most common, cost-effective |

Small dry-type transformers |

|

UI Core |

Easy to wind and assemble |

Power transformers |

|

Wound Core |

Low-loss, continuous lamination |

Distribution transformers |

|

Toroidal Core |

Compact, quiet operation |

High-frequency or precision devices |

For example, for rural electricity boards or commercial complexes, a 315kVA oil-immersed transformer often uses a wound core with silicon steel lamination and strong clamping for stability and silent operation.

Let's Talk Clamps: More Than Just Metal Straps

Clamps in transformers are often overlooked. But if you've ever had a transformer that failed insulation tests, had mechanical rattling, or even shifted core, chances are the clamping structure was the issue.

Key Clamp Functions:

Hold the core limbs and yokes in position

Maintain the tightness of the core stack

Reduce vibration and magnetostriction hum

Support lifting and mounting

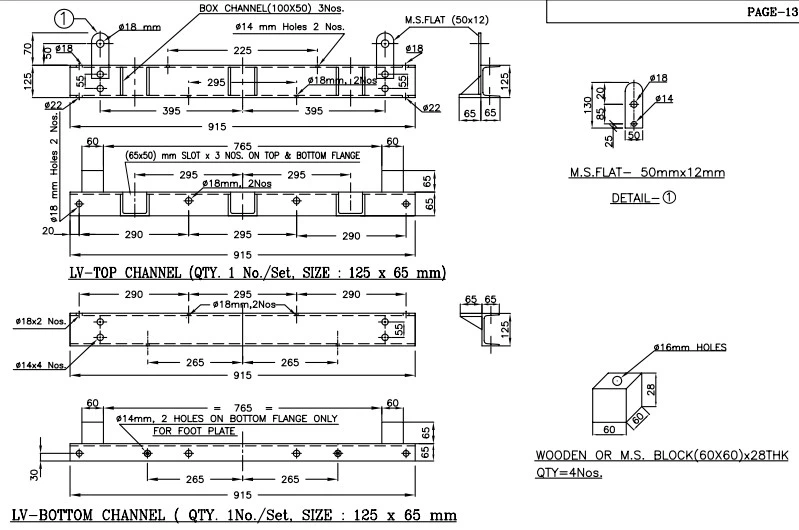

What You'll See on a Drawing:

Yoke clamp steel plate: often 8mm thick

Insulating pads are placed between the core and the clamp

U-clamp or L-clamp fixing bolts: located symmetrically

Core earthing point

Tip for Core Builders: Always make sure to tighten bolts with a torque wrench - too loose and you get vibration; too tight and you risk crushing insulation.

Common Core Sizes and Stack Arrangements (for 315kVA)

|

Parameter |

Typical Value |

|

Limb cross-section |

120 × 120 mm |

|

Core window (HxW) |

250 × 320 mm |

|

Stack thickness |

150–180 mm |

|

Clamp plate thickness |

8 mm (galvanized steel) |

|

Bolt size |

M16 or M20 |

How to Improve Core Efficiency

If you're a factory building 10–20 units a day, every point of energy saving matters. Here's how to boost performance:

Use high-grade CRGO steel (like M3/M4/M5) to reduce losses

Add interleaved stacking instead of step-lap for better flux flow

Apply varnish or anti-vibration coating

Earth the core at one point only - avoid double earthing

Use epoxy-coated clamp insulation pads

Clamp Material Choices: What Works Best?

|

Clamp Material |

Pros |

Where to Use |

|

Mild Steel |

Strong, cost-effective |

General-purpose transformers |

|

Galvanized Steel |

Rust-resistant, good insulation |

Outdoor units |

|

Stainless Steel |

Long life, high strength |

Coastal or humid regions |

Don't forget - clamps also need insulation tapes or sleeves between steel and copper parts to avoid short circuits.

What Transformer Buyers Care About (And How Your Core Matters)

If your customer is a utility company, EPC contractor, or electrical wholesaler, they want:

Silent, stable transformers

Guaranteed load capacity

No vibration or internal hum

Long service life

Easy onsite maintenance

Guess what influences all of that? The core and clamps.

So if you're building or supplying transformer cores, use standardized designs, test the clamping structure under vibration, and ship with all fixtures pre-assembled. You'll win customer trust.

Promisteel's Transformer Core Solutions

At Promisteel, we're not just a steel supplier - we're a transformer core solution provider.

We offer:

CRGO sheets in M2 to M6 grades

Custom E-type, EI, and wound core laminations

Pre-cut slit coils for your press machine

Core stacking jigs and clamp kits

High-quality insulated clamps ready for assembly

Whether you're a core builder in India, a transformer OEM in the Middle East, or a component wholesaler in Africa, we can supply precision-stamped cores and clamps that match your specs.

Build Smarter, Not Harder

Transformer cores and clamps may seem like small parts in the big picture, but they hold the key to transformer durability, noise reduction, and energy efficiency. With smart material selection, proper assembly, and strict testing, you'll build a better transformer every time.

If you need help sourcing transformer core steel or want ready-to-install clamp kits, get in touch with Promisteel. We speak your language - literally and technically.

Want to Learn More?

→ Contact our team today for a custom transformer core solution.

→ Email: sales@promisteel.com | WhatsApp: +86-185-2641-3298