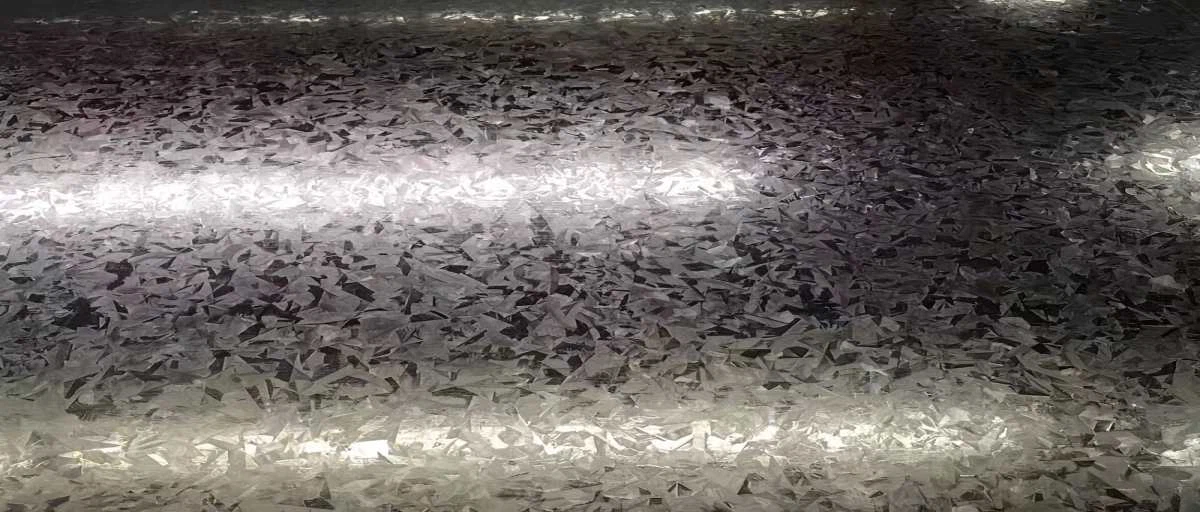

Have you ever looked closely at a galvanized steel sheet? Sometimes you see a beautiful, shiny pattern that looks like frost on a window. Other times, the surface is perfectly smooth and uniform.

That pattern is called spangle, and the difference between having it and not having it is one of the most important decisions you'll make when buying galvanized steel.

Choosing the wrong type can affect your product's final look, its ability to be painted, and even your costs.

So, what's the real story behind zero spangle vs. regular spangle? Let's break it down in a way that's simple and clear.

What is Spangle? The "Fingerprint" of Galvanized Steel

A Quick Science Lesson (Made Simple)

Think about water freezing into ice. As it freezes, it forms beautiful, unique ice crystals. Spangle is the same idea, but with zinc!

When a steel coil passes through the molten zinc bath, the liquid zinc cools and solidifies on its surface. As it solidifies, it naturally forms zinc crystals. Spangle is simply the visible pattern of these crystals.

The cool part is that we can control how these crystals form during the production process. We can let them grow big and beautiful, or we can stop them from forming altogether.

The Three Main Types of Spangle You'll See:

Regular Spangle: This is the traditional look with large, clearly visible crystals. It has a classic, shiny, decorative appeal.

Minimized Spangle: As the name suggests, the crystals are much smaller and less obvious.

Zero Spangle (or Spangle-Free): The surface is treated in a special way (usually with a "skin pass" roller) to prevent any visible crystals from forming. The result is an extremely smooth and uniform surface.

The Big Comparison: Zero Spangle vs. Regular Spangle at a Glance

Let's put them side-by-side. This simple table tells you almost everything you need to know.

|

Feature |

Regular Spangle |

Zero Spangle |

|

Appearance |

Shiny, visible crystal pattern (like snowflakes) |

Smooth, uniform, matte or mirror-like finish |

|

How It's Made |

Natural cooling of the zinc |

Controlled cooling and an extra "skin pass" step |

|

Best For... |

Industrial uses where appearance isn't critical |

High-quality painting and aesthetic applications |

|

Paint Adhesion |

Good, but may require light sanding for a perfect finish |

Excellent, provides the perfect base for paint |

|

Cost |

Standard (Base Price) |

A little bit more (due to the extra processing) |

Does Spangle Affect Corrosion Resistance? (A Common Myth Busted)

This is a question we get all the time. Many people believe that the larger, thicker-looking crystals of a regular spangle provide better rust protection.

The simple answer is: No, this is a myth.

The corrosion resistance of galvanized steel is determined by one thing: the thickness of the zinc coating (the Zinc Coating Weight, like Z275 or G90).

As long as a zero-spangle sheet and a regular spangle sheet have the same zinc coating weight, they will have virtually identical service lives. Don't choose a spangle type based on corrosion resistance; choose it based on your final application.

Which One Should YOU Choose? A Practical Decision Guide

This is the most important part. Here's how to make the right choice every time.

Choose REGULAR Spangle IF...

Your primary goal is cost-effective, long-term rust protection.

The product will NOT be painted.

The final look is industrial, agricultural, or rustic.

Perfect for: Corrugated roofing sheets, highway guardrails, water tanks, farm equipment, and structural components where the raw metallic look is acceptable or desired.

Choose ZERO Spangle IF...

You ARE GOING TO PAINT the product. This is the number one reason to choose zero spangle. Its perfectly smooth surface ensures a flawless, high-quality paint finish without any of the spangle patterns showing through.

You need a sleek, modern, and uniform appearance.

Your application is a high-value consumer product.

Perfect for: Home appliances (refrigerators, washing machines), automotive parts, electrical cabinets, high-end architectural panels, and any application that demands the best galvanized steel for painting.

Getting the right finish is critical for your product's success. At PromiSteel, we supply the full range of spangle types. We can help you decide whether the small extra investment in a spangle-free GI coil will pay off tenfold in your finished product.

Contact Us to Discuss Your Finishing Requirements

It's Not Just a Look, It's a Technical Choice

Choosing between zero spangle and regular spangle is a key technical decision. It's about matching the surface of the steel to the demands of your project.

To put it simply:

Regular Spangle = Durability on Display.

Zero Spangle = The Perfect Canvas.

Now you know the difference and can specify exactly what you need with confidence.

Have a project that requires a perfect paint finish? Or need a cost-effective solution for an industrial application?

[Tell us about your project]. Our team will provide you with a professional recommendation and a competitive quote for the perfect galvanized steel.